- Wide variety of gauge options with gauge accuracy of +/- 2% or better full deflection

- Models available with no gauge, custom fills, and factory installed instrumentation provided by customer

- Housings are unconditionally guaranteed for life not to fail or Blacoh will replace them at no cost

- Easily installed, come in a variety of chemically resistant materials, and work in both pressure and vacuum conditions

- Protect gauges and other system instrumentation from process fluid contamination and corrosion.

- Accurately transfer process pressure without direct contact with process fluids.

- Prevent erratic surges and clogging due to solids in process fluids.

- Protect gauges from freezing and slurries.

- Ensure accuracy and reliability of pressure instrumentation when working with corrosive or solids-laden fluids.

- Reduce costs by replacing expensive gauges with low cost utility gauges.

- Proudly made in the USA

HOUSING MATERIALS: CPVC, Polypropylene, PVC, PVDF, Alloy 20, Stainless Steel

BLADDER MATERIALS: EPDM, PTFE,

INLET SIZES: 0.25" (8mm), 0.5" (15mm), 0.75" (20mm)

INLET TYPES: FNPT, BSP, ANSI Flange, Socket Weld, Tri-clamp, Union

MAX PRESSURE: 200 psi (13.7 bar), PVDF 250 psi (17.2 bar), METAL 1000 psi (68.9 bar)

CERTIFICATIONS & TESTING: ARRA, 3.1 Cert, Cert of Origin

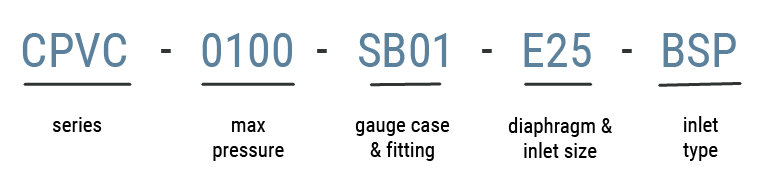

MODEL NUMBER FORMAT

Example model number:

| Series |

Wetted/Nonwetted |

| CPVC |

CPVC |

| PP |

Polypropylene |

| PVC |

PVC |

| PVDF |

PVDF |

| A20 |

Alloy 20 |

| SS |

Stainless Steel |