Injection quills seem so simple yet they are powerful pieces of equipment that serve two very important purposes:

- A safe and effective way to connect a liquid chemical feed to a pipeline or vessel

- Chemical delivery directly into the center of the process flow—aiding in mixing and protection of pipe

The Engineering Behind Injection Quills

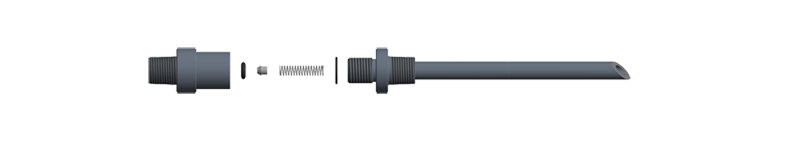

Manufacturing engineered injection quills is more involved than you might think. Injection quills are designed for safety and ease of operation. Each component is CNC machined for precision.

The internal spring-loaded check disk prevents process fluid backflow into the chemical feed and stops chemical flow when the pump is shut down or the chemical feed is disconnected. Adding to the complexity, a variety of chemically resistant materials, connection sizes, and quill lengths are offered to expand the application reach.

The Importance of Quill Location

Ideally, injection quills are installed so that the chemical is delivered directly into the center of the pipeline where flow velocity is highest to ensure even dispersion throughout the flow and a more thorough mix. This direct injection into the center of the flow also avoids chemical contact with the injection port and prevents undiluted chemicals from coming into contact with the pipe wall.

The Applications

- Water Treatment: Injection quills deliver chlorine, coagulants, and pH adjusters into water treatment systems for disinfection, impurity removal, and maintaining water quality

- Oil & Gas: In this sector, injection quills help deliver chemicals for pipeline maintenance, corrosion inhibition, scale prevention, and enhanced oil recovery during production

- Pharmaceuticals: Injection quills play a role in drug synthesis by accurately introducing active pharmaceutical ingredients (APIs) and other substances

- Wastewater Treatment: Injection quills are used for chemical injection of flocculation, coagulation, and pollutant removal in wastewater treatment plants

- Chemical Manufacturing: Injection quills precisely deliver catalysts, reactants, and additives into reaction vessels

In a Nutshell

As simple as they may seem, injection quills play a vital role in dispersing concentrations of corrosive chemicals safely and efficiently across a wide range of critical applications.

Got questions? Contact us for more info!